Flange Coupling

As one of the leading flexible flange coupling manufacturers, suppliers, and exporters of products, We offer flexible flange coupling and many other products.

Please contact us for details.

Mail:[email protected]

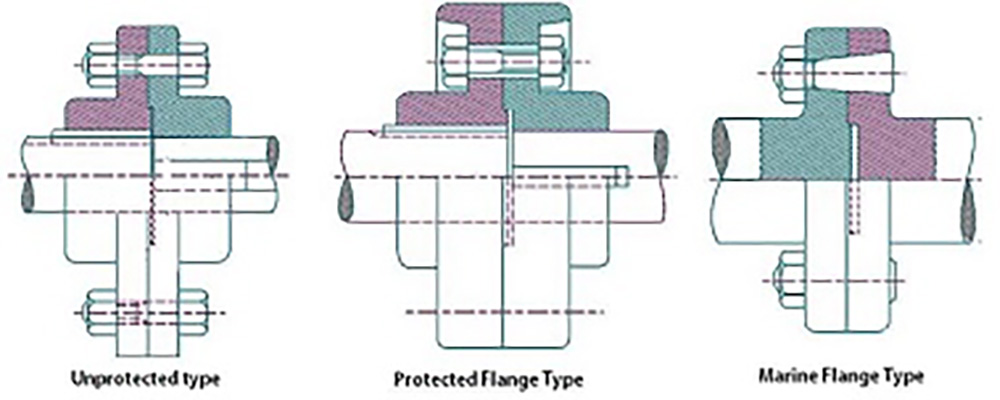

When it comes to “Rigid Couplings”… this is about as rigid as it gets. The “Flange Coupling” is very simple to describe. It is made up of two hubs (that fit on the equipment shafts), with those hubs being machined with a multi-bolt flange on one end. When the equipment is “coupled”, the flanges are bolted together and basically become ONE LARGE MASS! How simple can it get?

While we’ve described the “Flange Coupling” as being a RIGID coupling, there are hybrid designs that use “rubber” (or some other flexible/soft material), as a bushing, normally inside the bolt holes of one of the flanges. The application of this flexible material allows the “Flange Coupling” to withstand some misalignment and afford a small degree of flexibility and vibration damping to an otherwise very rigid device.

A “Flange Coupling” transmits the highest values of load, as any shaft coupling design on the market. The concept of torque transmission may be described differently by various manufacturers, while the method of attachment and connection will remain basically the same among the. One manufacturer will tell you that it is the “clamping force” of the bolts, causing high friction between the faces of the flanges, is what actually transmit the power, while another will say that the mechanical strength of the bolts is actually the method of power transmission. In either case, this type of shaft coupling transmits 100% of the power from the driver to the driven equipment, with no loss due to flexing of components. And while this is all true, ONE thing that stands out as a “con”, is that with zero ability to withstand angular and/or parallel misalignment, equipment alignment is VERY critical. We definitely recommend “Laser Alignment” or expert dial indicator alignment during the installation process.

“Flange Couplings” can be purchased with a “pilot bore”, where you can have the hubs bored and keyed as necessary; or you can have them “bored to size” to minimize any added expense and time after purchase. Lastly, the hubs can be purchased as a “bushed” type of bore, where you can purchase the proper size “taper-lock” type bushing to suit the application. This last type allows for use of the coupling on a different machine… down the road.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2:Do you provide samples ? is it free or extra ?

A: : Yes, we could offer the sample, while you may need to pay the sample cost according to the products values. Actually we have a very good price principle, when you make the bulk order then cost of sample will be return to you.

Q3: How long is your delivery time?

A: Generally it is about 2 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q4:How long is your warranty?

A: Our Warranty is 12 month.

Q5 :Do you have inspection procedures for coupling ?

A:100% self-inspection during production and before packing.\

Q6. What’s your payment?

A: 30% deposit before prodction, balance before shipment or against copy of B/L.

Q7:Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

As one of the leading flexible flange coupling manufacturers, mechanical product suppliers and exporters, we supply flexible flange coupling and many other products for cluster flexible flange coupling. flexible flange coupling, flexible flange coupling Manufacturer, flexible flange coupling Supplier, flexible flange coupling Exporter, flexible flange coupling Seller, flexible flange coupling Made In China, Wholesale flexible flange coupling, Buy flexible flange coupling, Customize flexible flange coupling – Find flexible flange coupling Manufacturers and Suppliers. Choose from quality driveshaft manufacturers, suppliers and exporters on flexibleflangecoupling.com.

Flexible Flange Coupling

Flexible flange couplings are used to connect two shafts, end-to-end on the same line, for two primary purposes. The first purpose is to transfer power as torque from one shaft to the other so that both shafts rotate in unison at the same RPM. The second purpose is to compensate for small misalignments and random movements between the two axes.

Flexible flange couplings are made of elastic materials, such as rubber, or have various other configurations. During rotation, the elastic coupling can accommodate misalignment and movement.

How flexible flange coupling operates?

It is well known that in any direct mechanical drive system, it is necessary to couple the various driven elements involved. Most drive elements, including gear reducers, lead screws, and many other components, are operated through shafting. The shafting is supported by a plurality of bearings. This allows the shafting to remain very straight and rigid as it rotates, while avoiding any possible balance and support issues. Due to this rigid support, it is almost impossible to avoid a slight misalignment between the drive shaft and the driven shaft when they are connected.

The simple and most common solution to the problem of shaft misalignment is using a flexible coupling to absorb lateral, angular, and axial restoring forces, while maintaining some rigidity or fixed position in rotation. The degree to which this torsional rigidity is applied varies from one application to another. The basic function of flexible coupling is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both.

our company

Hangzhou Ever-power Transmission Co., Ltd. Is a specialist in making all kinds of mechanical transmission and hydraulic transmission like:

Parallel shaft helical gear reducers, planetary gearboxes, worm reducers, in-line helical gear speed agricultural reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vaccum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars, low backlash worm reducers and so on.

Furthermore,we can produce customized variators,geared motors, electric motors and other hydraulic products according to customers’drawings.

We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.

We warmly welcome customers both at home and abroad to contact us to negotiate business,exchange information and cooperate with us.

We staff over 1500 workers, and have cnc turning machines and cnc work centers.

We are one of the best manufacturer and supplier in china, choose quality manufacturers, suppliers,exporters at hzpt.com.